Product Category

Water Treatment Plants

Industrial RO Plant

Seawater Desalination Plant

Containerized RO Plant

SS RO Plant

Dialysis RO Plant

Ultra Filtration Plant

Sewage Treatment Plant

Water Softening Plant

Filtration System

Mineral Water Plant

Fully Automatic Mineral Water Plant

Alkaline Mineral Water Plant

Automatic Mineral Water Plant

Mineral Water Bottling Plant

Packaged Drinking Water Plant

Turnkey Mineral Water Project

Mineral Water ISI Plant

Water Plant Machinery

Drinking Water Plant

Automatic Pet Bottle Filling Machine

Mineral Water Filling Machine

Packaged Drinking Water Filling Machine

Automatic Pet Bottle Rinser Filler Capper Machine

Water Bottle Filling Machine

Mineral Water Packing Machine

Automatic Drinking Water Filling Machine

Carbonated Soft Drinks Filling Machine

Juice Bottle Filling Machine

Fully Automatic 20 Liter Jar Rinsing Filling Capping Machine

Automatic 20 Liter Jar Filling Machine

Shrink Wrapping Machine

Blow Moulding Machine

Labelling Machine

Automatic Sticker Labelling Machine

Automatic Sleeve Applicator

Automatic BOPP Hot Glue Labelling Machine

Mineral Water Non ISI Plant

Commerical Alkaline Ionizer

Carbonated Soft Drink Plant

Carbonated Soft Drink Production Line

Beverage Manufacturing Plant

Carbonated Beverage Manufacturing Plant

Carbonated Soft Drink Filling Plant

Soft Drink Manufacturing Plant

Soft Drink Making Machinery

Fully Automatic Soda Soft Drink Plant

Beverage Making Plant

Automatic Carbonated Soft Drink Plant

RO Spares

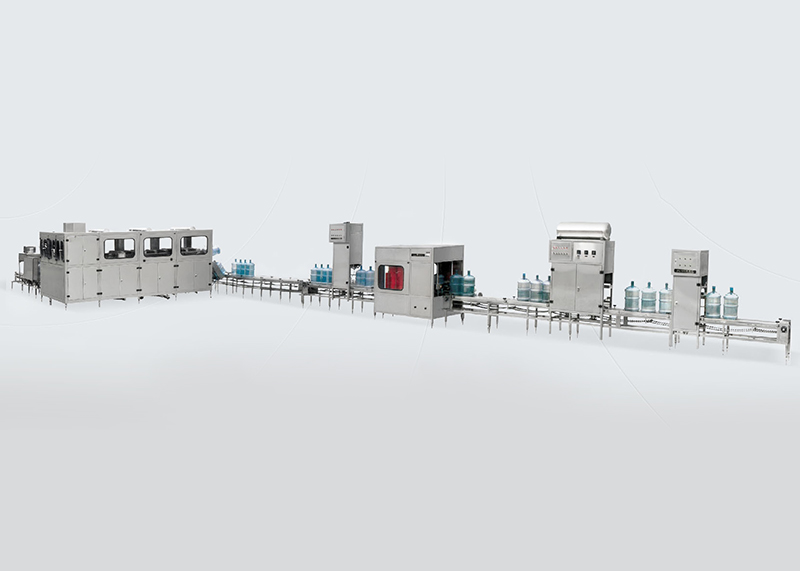

Automatic 20 Liter Jar Filling Machine

We are one of the leading Manufacturers, Suppliers, Traders and Distributors, of this highly commendable range of Automatic 20 Liter Jar Filling Machine

Request A QuoteProduct Description

Unitech Water Solution is an Exporter & Manufacturer of Automatic 20 Liter Jar Filling Machine. Our series 20 Liter (5 Gallon) Jar Filling machine integrates Bottle Washing, Water Filling and Capping into one monoblock, and the three processes are carried out full automatically. It is used in the filling of mineral water, pure water, and other non-carbonated beverage. Each machine element that contacts with the liquid is made of high quality SS 304. It is with advantages of high automation, easy operation, good abrasive resistance, high stability, low failure rate, etc.

Features

- External Brushing Machine

- 5 Stage Washing (Including Hot Water)

- Equipped with Infeed Conveyor, Auto Loader & Exit Conveyor

- HMI / PLC Base Touch Screen Panel

Technical Specification

| Sr No | Model | UWS 120 | UWS 240 | UWS 400 | UWS 600 | UWS 900 | UWS 1200 |

|---|---|---|---|---|---|---|---|

| 1 | Production Capacity (JPH) | 120 | 240 | 400 | 600 | 900 | 1200 |

| 2 | Head | 1 | 2 | 3 | 4 | 6 | 8 |

| 3 | Bottle Size | 20 Liter | |||||

| 4 | Exit Conveyor (Meter) | 3.0 | 3.0 | 5.0 | 5.0 | 5.0 | 5.0 |

| 5 | Pressure (Mpa) | 0.4 - 0.6 | 0.4 - 0.6 | 0.4 - 0.6 | 0.6 | 0.6 | 0.6 |

| 6 | Air Consumption (m3/min) | 0.37 | 0.6 | 0.8 | 1 | 1.5 | 1.8 |

| 7 | Power | 1.5 | 3.0 | 5.0 | 7.5 | 11.0 | 15.0 |

| 8 | Filling Nozzle (MOC) | SS 316 | |||||

| 9 | PLC / HMI | UWS | UWS | UWS | Delta | Delta | Delta |

| 10 | Machine Type | Mechanical (Linear) | |||||

| 11 | Switch Gear | Schneider | |||||

| 12 | Type of Filling | Gravity Filling | |||||

| 13 | Suitable Cap | Plastic Screw Cap / Plastic Push Cap | |||||